Innovative Solutions For Better Aseptic Processing

We are dedicated to design, innovate perfect solutions and manufacture quality aseptic processing equipment for bio-tech, pharmaceutical, new energy industry over the world.

Eshop

News

Events

Engineering

Quality

Solutions

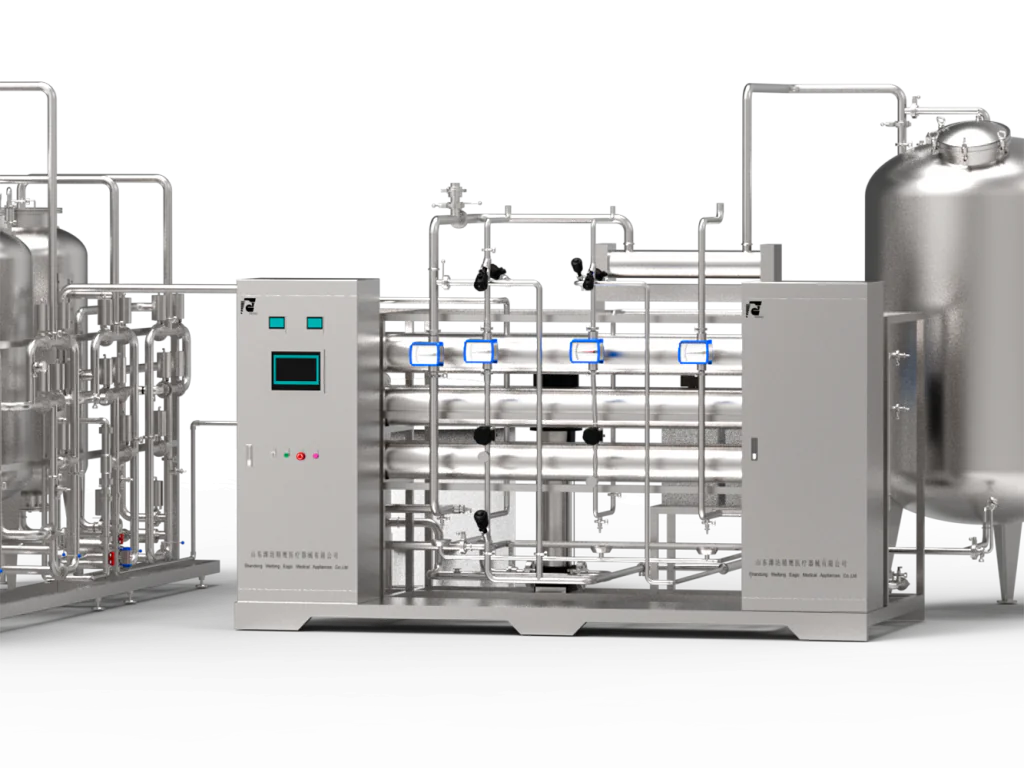

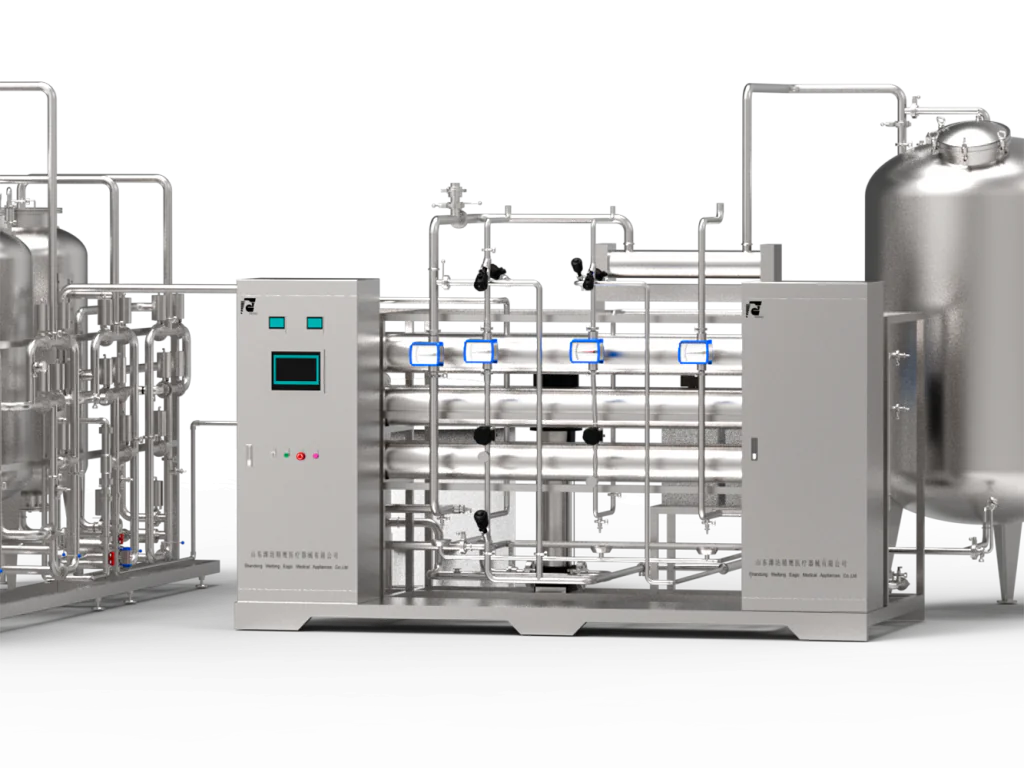

Purified Water Solutions

Operate as cGMP-regulated manufacturing, the PW water treatment equipment we finished is widely used in bio technology, pharmaceutical, new energy and chemical industry.

WFI Solutions

Eagle’s LDS series Multi Effect Still adopted the purified water as the feed water, produced WFI by heating industrial steam. The product satisfies the requirement of USP,EP and JP.

Pure Steam Solutions

Eagle Pure Steam Generators are used to produce pure steam which is widely used for sterilization of pharmaceutical equipment and production piping line and storage tanks. When condensed, meets CGMP,USP,EP and JP.

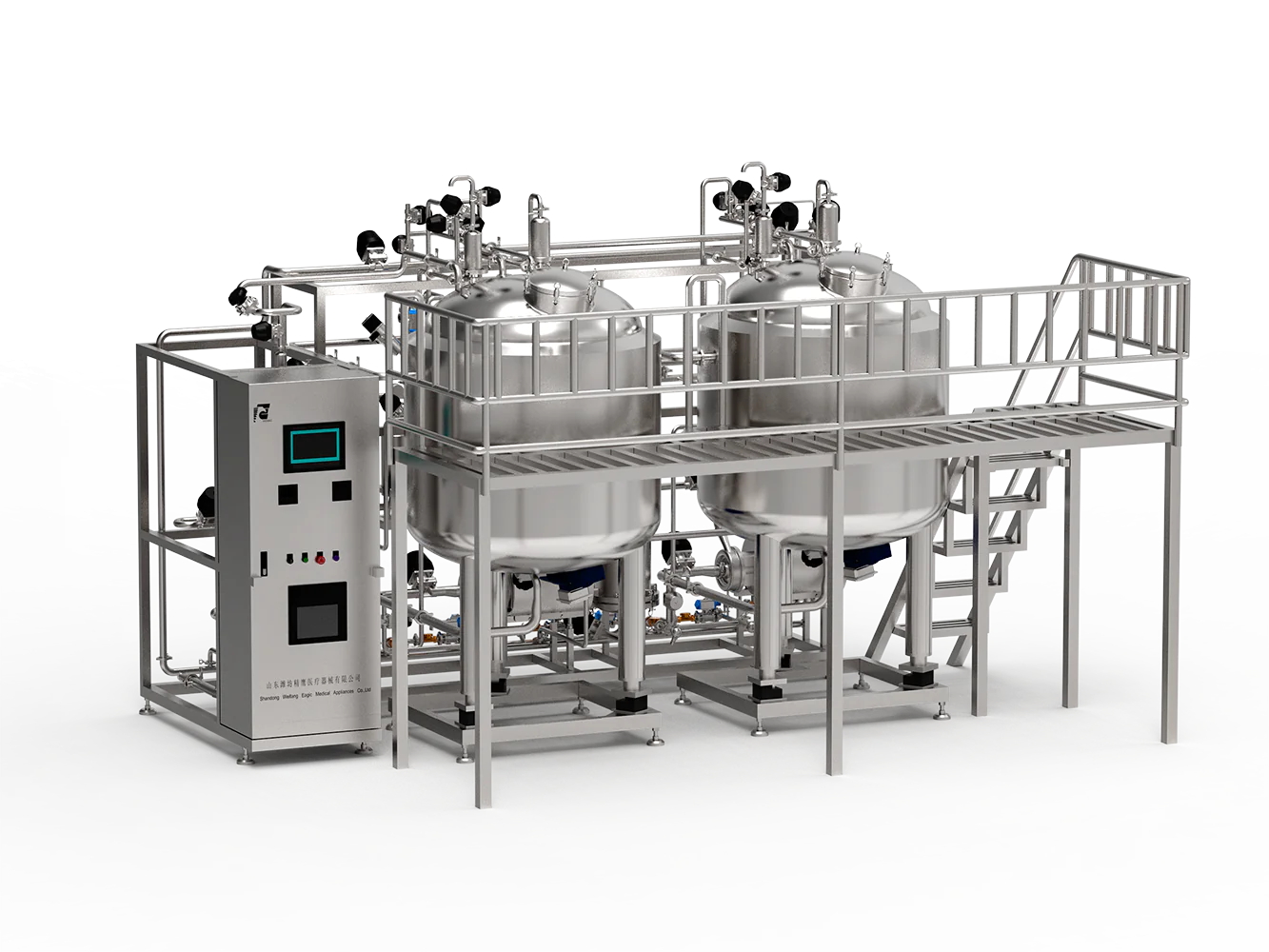

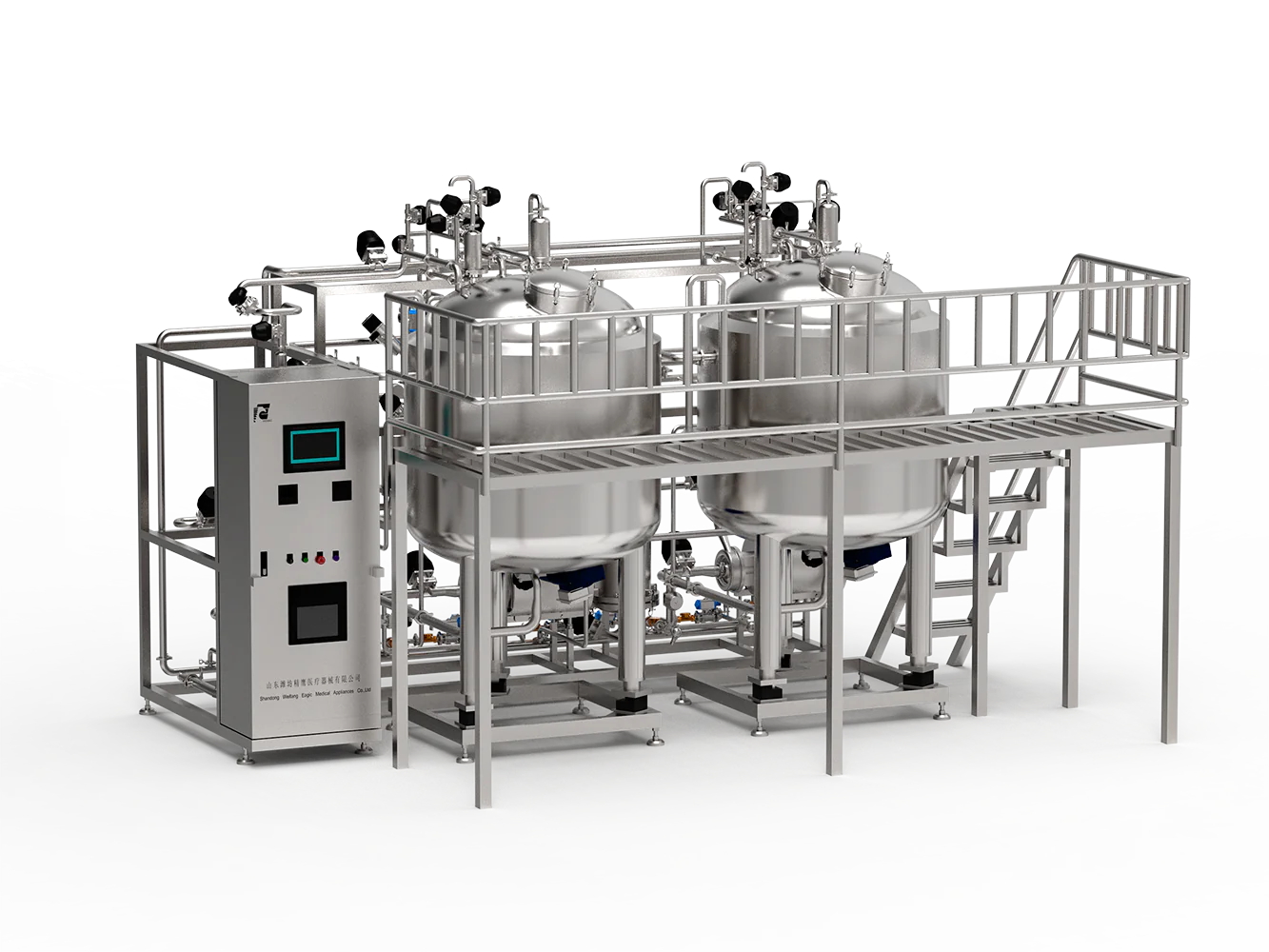

Liquid Preparation Solutions

LPS features hygienic pipes and fittings to eliminate dead legs and contamination, with controlled recirculation ensuring full compliance with customer requirements and validation criteria and recipes.

Extraction Solution

SKE multi functional extraction equipment can meet the needs of all solid-liquid extraction, with a very wide application range. It can be used for extracting active ingredients from dry & wet leaves, stems, bark, toots, fruits and vegitables, etc.

Brewery & Beverage Solutions

SKE with cut-edge engineering, bespoke quality production equipment for food & beverage, brewing, distilling, diary, industries.

Featured Products

Purified Water Generator

Two Stage RO System with EDI

Liquid Preparation System

Multi-effect water distiller adopted the purified water as the feed water, produced WFI (water for injection) by heating industrial steam. Eagle’s LDS series Multi Effect Still adopted the purified water as the feed water, produced WFI by heating industrial steam. The product satisfies the requirement of USP,EP and JP.

Eagle skid-mounted assemblies integrate all monitoring instruments and control devices for the WFI distribution system into a compact unit, which is fully assembled and integrated with a PLC (Programmable Logic Controller) system.

Discover Liquid Food &

Beverage Processing Solutions

Upcoming Events

Feb 18, 2025

FY 2024 | Publication Annual Report

Feb 18, 2025

FY 2024 | Publication Annual Report

Featured Blog Stories

EDI Systems

EDI Systems in Reverse Osmosis Purified Water: A Technical Analysis and Mainstream Brand Guide

Heat Exchanger

Double-Tube-Sheet Heat Exchanger: Dual Guarantee of Safety and Efficiency in Industrial Heat Exchange Scenarios

Pharmaceutical Pipeline

Principles of Pharmaceutical Water Pipeline Design: Dual Assurance of Compliance and Safety

A Trusted Partner of Biopharmaceutical, Brewery,

Beverage and New Energy Industry

Responsibility At Every Step

To become the world's leading service provider and manufacturer of high quality turnkey projects for breweries, beverage factories and pharmaceutical factories.

World lever fully automatic production line,

Make sure to delivery perfect project.

Eagle engineers know:

· USP34 & EP7

· Pressure Vessel Design

· ASME Standard

· Certifications for PED/AS1210 etc.

· Flow design for Pharma water, brewing, distilling, beverage

· UL/CUL/CE

ASME

PED

AS1210

C/UL

CE

ISO

FAD

Work With Us Together

CERISHING LIFE, NOBLE RESPONSIBILITIES

We innovate solutions for better aseptic processing.Work with us together.