Multi Effect Still

Wide use of Water for Injection (WFI) from Multi-effect Still

- Solvent for Injectables: Used as a solvent in the formulation of various injectable preparations.

- Cleaning: For the final rinse of containers (e.g., vials, ampoules) and equipment for sterile products.

- Sterile API Production: Employed in the final purification steps of sterile active pharmaceutical ingredients (APIs).

- Other High-Risk Products: Used in the manufacture of ophthalmic and inhalation solutions.

Work Principle

- Pre-processing: Feed water (always purified water) is preheated through a heat recovery system (Final Condenser and preheaters).

- 1st Effect Evaporation & Separation: The preheated water is distributed as a falling film, boiled by industrial steam, and the resulting vapor-liquid mixture is separated via falling film, gravity, and centrifugal separation.

- Energy Cascade: The separated pure steam heats the next effect, while the concentrated water is forwarded; this process repeats in subsequent effects.

- Distillate Convergence & Final Condensation: Condensate from all effects (except the 1st-effect) and pure steam from the final effect are condensed in the Final Condenser.

- NCG Venting & Quality Control: Non-condensable gases are vented; the product water is continuously monitored for conductivity, TOC, etc., and only compliant water is accepted as WFI.

Product Feature

- Structural Form: External preheater, condenser, and first-effect evaporator feature a double tube sheet design with inner expansion and outer welding to prevent cross-contamination.

- Separation Device: Utilizes a three-stage separation process: falling film evaporation, gravity separation, and centrifugal separation.

- Material Quality: All parts contacting feed water, WFI, and pure steam are constructed from SS316L.

- Thermal Insulation: Evaporator, preheater, and condenser insulated with lightweight, high-stability aluminum silicate needled blanket for superior thermal performance.

- Surface Treatment: Internal and external surfaces electrochemically polished to ensure high smoothness.

- Energy Saving: Reuse of pure steam across effects significantly reduces industrial steam and cooling water consumption. Five-effect models use minimal cooling water; six-effect models require none.

- Piping: Pipes bent by stretching to minimize welding. Automated argon-protected welding (single-side weld, double-side formation) ensures quality, followed by electrochemical polishing.

- Validation Documentation: Includes endoscopy photos, weld maps, pressure test reports, pickling/passivation records, and system design documents.

- Control System: Fully automated HMI+PLC control with user-friendly interface, multi-protocol support, and at least three-level access permissions.

- Online Monitoring: Tracks conductivity, temperature, and flow. Supports paperless or paper recorders for data logging and printing.

- Optional Features: Electronic signatures/records, audit trail functionality, compliance with GAMP 5 and 21 CFR Part 11.

Relative Products

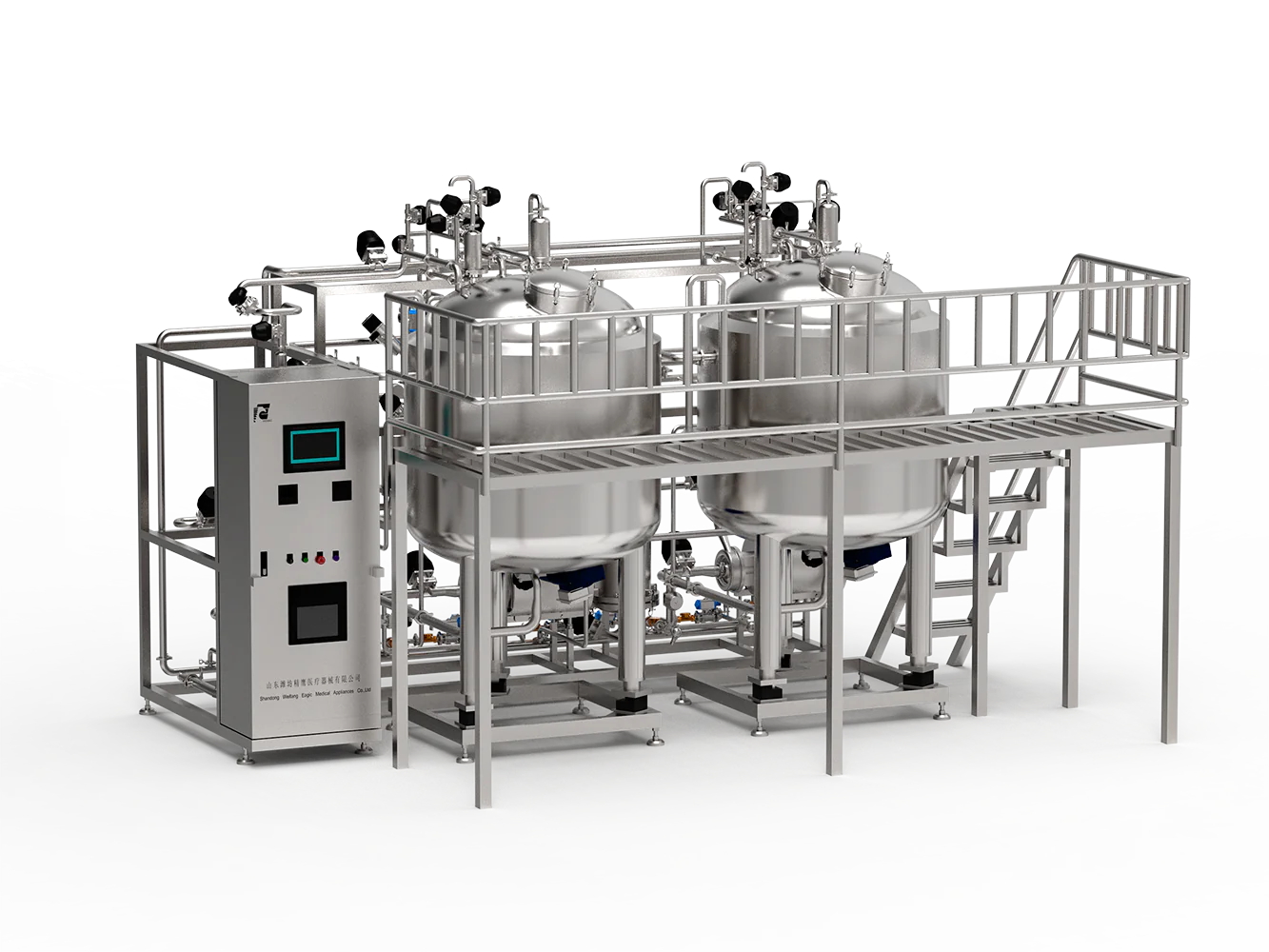

Liquid Preparation System

Eagle’s Liquid Preparation System (LPS) is a high-end automated platform that integrates precision, efficiency, and compliance. At its heart, it employs advanced process design to achieve precise weighing, transfer, and homogeneous mixing of diverse materials, perfectly meeting the stringent production standards from Small Volume (SVP) to Large Volume Parenteral (LVP) in the pharmaceutical industry.

Water Storage & Distribution System

Eagle skid-mounted assemblies integrate all monitoring instruments and control devices for the WFI distribution system into a compact unit, which is fully assembled and integrated with a PLC (Programmable Logic Controller) system.

Purified Water Generator Two Stage RO System with EDI

Eagle has been at the forefront of water treatment innovation for nearly 70 years, specializing in advanced Purified Water Generation systems tailored for the pharmaceutical industry. Our comprehensive turnkey solutions seamlessly transform raw tap water into high-purity water, optional with integrated storage and distribution systems.

Work With Us Together

CERISHING LIFE, NOBLE RESPONSIBILITIES

We innovate solutions for better aseptic processing.Work with us together.