Overview of Water Usage and Treatment in Food Industry

Water is an indispensable core resource in the global food manufacturing industry, serving as a direct raw material, processing medium, cleaning agent, and cooling medium throughout the production chain. From dairy pasteurization to beverage blending, from fruit and vegetable washing to meat processing sterilization, water quality directly determines product safety, quality stability, and compliance with regulatory standards. Food processing water includes raw material water (for product formulation), process water (for cooking, blanching, and mixing), cleaning water (for equipment CIP and environmental sanitation), and cooling water (for process temperature control).

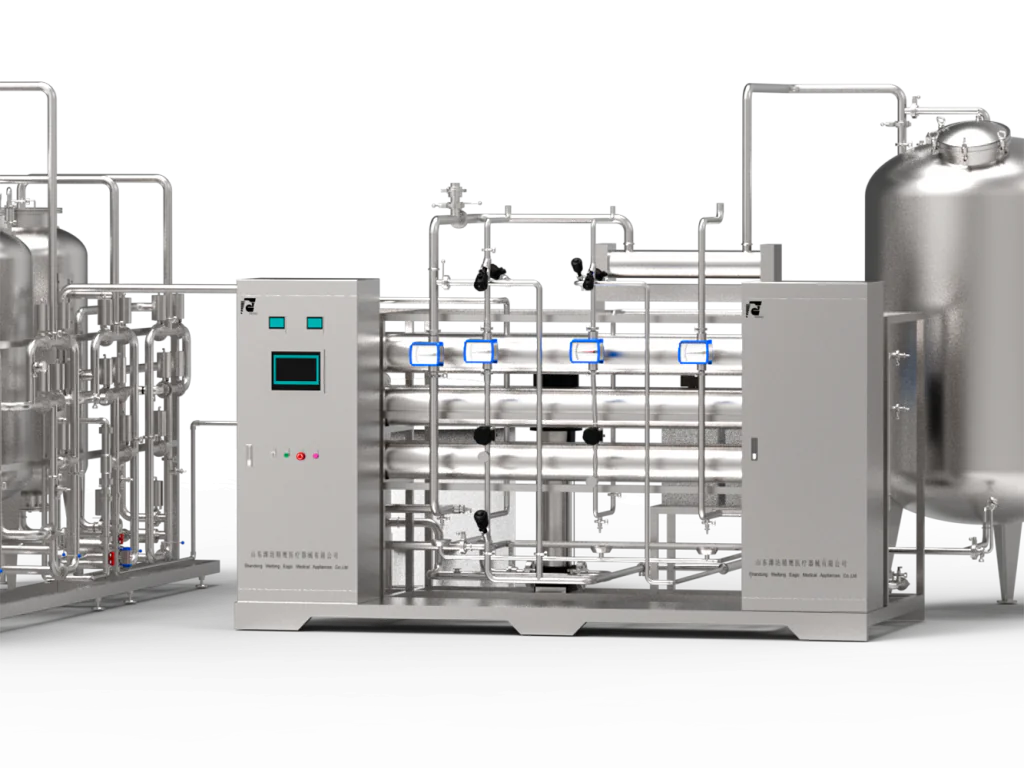

Given the strict requirements of food safety, raw water (tap water, groundwater, or surface water) must undergo targeted treatment processes such as purification and pure water preparation to remove impurities, microorganisms, harmful substances, and other pollutants before use. Water treatment systems have thus become a vital part of food processing infrastructure, as critical as production equipment itself. Leading food processing equipment manufacturers such as SKE & Eagle integrate customized water treatment solutions into end-to-end production lines, ensuring that water quality meets the specific needs of different food sectors while complying with global hygiene and safety standards.

Key Technologies for Water Treatment in Food Industry

Modern food industry water treatment relies on a combination of physical, chemical, and biological technologies, with core processes covering purification pretreatment, pure water preparation, disinfection, and recycling. These technologies are tailored to different water quality requirements (such as drinking water standard, pure water, or ultra-pure water) and production scenarios, ensuring both water safety and resource efficiency.

- Purification Pretreatment: The Foundation of Water Quality

Pretreatment aims to remove large particles, colloids, turbidity, and partial organic matter from raw water, protecting subsequent advanced treatment equipment. Core technologies include:

- Filtration Systems: Sand filters, activated carbon filters, and precision filters are commonly used. Sand filters remove suspended solids and turbidity; activated carbon adsorbs residual chlorine, organic matter, and odors, improving water taste and protecting reverse osmosis membranes; precision filters (with 5μm or smaller pores) trap fine impurities, preventing membrane fouling.

- Softening Treatment: For high-hardness raw water (common in dairy, beverage, and bakery industries), ion exchange resins or reverse osmosis (RO) technology is used to reduce calcium and magnesium ions, avoiding scale formation in heat exchangers, pipelines, and boilers, which could affect heat transfer efficiency and contaminate products.

- Coagulation and Sedimentation: For surface water with high turbidity (e.g., used in fruit and vegetable processing), coagulants are added to aggregate colloidal particles, which are then removed by sedimentation and filtration, ensuring subsequent treatment efficiency.

- Pure Water Preparation: Meeting High-Standard Production Needs

Many food sectors (beverage, dairy, confectionery, and pharmaceutical-grade food) require pure water with low conductivity, minimal impurities, and no microorganisms. Core pure water preparation technologies include:

- Reverse Osmosis (RO) Technology: The most widely used core technology in food industry pure water preparation. RO membranes with nanoscale pores can remove 99% of dissolved salts, microorganisms, organic matter, and colloids. SKE & Eagle’s customized RO systems feature high-pressure resistant membranes and intelligent control systems, ensuring stable water production (conductivity ≤10μS/cm) and low energy consumption, suitable for beverage blending, dairy product processing, and other scenarios.

- Ultrafiltration (UF) Technology: Used for semi-pure water preparation or as RO pretreatment. UF membranes remove macromolecular organic matter, bacteria, and viruses while retaining small-molecule nutrients, making it suitable for fruit juice concentration, dairy protein separation, and other processes requiring retention of specific components.

- Electrodeionization (EDI) Technology: Combined with RO for ultra-pure water preparation (conductivity ≤0.1μS/cm), used in high-end beverage, food additive production, and other scenarios requiring extremely high water quality. EDI achieves continuous deionization through ion exchange and electrolysis, avoiding chemical regeneration and reducing environmental pollution.

- Disinfection and Sterilization: The Last Line of Defense for Food Safety

Even after purification and pure water preparation, water must be disinfected to eliminate residual microorganisms (bacteria, viruses, spores) and prevent product contamination. Common technologies include:

- Ultraviolet (UV) Disinfection: Physical disinfection method with no chemical residues. SKE & Eagle’s UV disinfection systems use high-intensity UV-C lamps to inactivate microbial DNA, suitable for drinking water, pure water final disinfection, and equipment cleaning water treatment, widely applied in dairy, beverage, and bakery industries.

- Ozone Disinfection: Strong oxidizing property, capable of rapid disinfection and degrading organic pollutants. Used in bottled water, fruit and vegetable washing water, and equipment CIP systems. Ozone decomposes into oxygen, leaving no residues, but requires strict concentration control to avoid affecting product taste.

- Chemical Disinfection: Chlorine or chlorine dioxide disinfection, used for large-scale raw water pretreatment or cooling water disinfection. It is cost-effective but requires strict control of residual chlorine to avoid chemical reactions with food components.

- Water Recycling: Sustainable Development Trend

With the increasing emphasis on environmental protection and resource conservation, water recycling has become a key direction in food industry water treatment. SKE & Eagle’s integrated water recycling systems treat process wastewater (such as cleaning water, cooling water) through filtration, disinfection, and reverse osmosis, making it reusable for non-product contact scenarios (equipment cleaning, floor washing, cooling) or even product contact after advanced treatment. This reduces water consumption by 30-50% and lowers sewage discharge costs, aligning with global carbon neutrality goals.

Engineering and Design Considerations for Water Treatment Systems

Designing food industry water treatment systems requires comprehensive consideration of raw water quality, production process requirements, regulatory standards, and operational efficiency, following the principles of “fit for purpose, safety first, and sustainability.”

- Raw Water Quality Analysis: Conduct detailed testing of raw water (turbidity, hardness, conductivity, microorganisms, heavy metals) to determine the appropriate treatment process. For example, high-fluoride groundwater requires defluoridation pretreatment, while surface water with high organic matter content needs enhanced activated carbon adsorption.

- Process Matching with Production Needs: Tailor water quality indicators to different food sectors. For example, bottled water requires ultra-pure water with conductivity ≤1μS/cm; dairy pasteurization water requires soft water to avoid scale formation in heat exchangers; fruit and vegetable washing water requires low-residual chlorine disinfection to protect product freshness.

- Material Selection for Sanitary Safety: All system components in contact with water (pipelines, valves, tanks, membranes) must use food-grade materials such as 316L stainless steel, food-grade plastic, or ceramic. SKE & Eagle adopts electropolished stainless steel pipelines and sanitary clamp fittings to ensure smooth surfaces, no dead zones, and easy cleaning, complying with 3-A and EHEDG standards.

- Intelligent Control and Monitoring: Integrate IoT sensors and PLC control systems to monitor key parameters (flow rate, pressure, conductivity, residual chlorine, microorganism count) in real time. Implement automatic adjustment (such as VFD for pump speed control, automatic chemical dosing) and remote monitoring to ensure stable water quality and reduce manual intervention.

- Easy Maintenance and Sanitation: Adopt modular design for easy disassembly and maintenance of equipment (such as replaceable filter elements, removable membrane modules). Design CIP (Cleaning-in-Place) interfaces for tanks and pipelines to facilitate regular cleaning and sterilization, preventing microbial contamination.

Innovations and the Future of Water Treatment in Food Industry

Driven by food safety requirements, environmental protection policies, and technological progress, food industry water treatment is moving toward intelligence, high efficiency, and sustainability. Key innovation trends include:

- Intelligent Water Treatment: Integrate AI and machine learning algorithms to analyze raw water quality and production load data, optimizing treatment process parameters (such as chemical dosing amount, membrane operating pressure) in real time. SKE & Eagle’s smart water treatment systems realize automatic adaptation to raw water quality changes, ensuring stable water quality while reducing energy consumption.

- Advanced Membrane Technologies: Develop high-performance membranes (such as anti-fouling RO membranes, high-flux UF membranes) to improve water treatment efficiency and reduce maintenance costs. Research on graphene membranes and ceramic membranes aims to achieve higher rejection rates and longer service lives.

- Green and Low-Carbon Technologies: Promote energy-efficient equipment (such as high-efficiency pumps, energy recovery devices) and renewable energy (solar, wind) power supply for water treatment systems. Develop biodegradable disinfectants and chemical agents to reduce environmental impact.

- Full-Process Traceability: Establish digital water quality traceability systems, recording raw water testing, treatment process, water use, and wastewater discharge data throughout the process. Realize full traceability of water quality for each production batch, improving regulatory compliance and product safety.

Frequently Asked Questions

- Why is water treatment critical in the food industry?

Water is a core resource in food production, and its quality directly affects product safety (preventing microbial and chemical contamination), quality stability (taste, texture, shelf life), and regulatory compliance. Poor water quality can lead to product spoilage, foodborne illnesses, and regulatory penalties. Water treatment ensures that water meets the specific requirements of different food production processes.

- What are the key differences in water treatment requirements between different food sectors?

Beverage industry requires ultra-pure water with minimal impurities to ensure taste and shelf life; dairy industry focuses on soft water (to avoid scale) and sterile water (to prevent bacterial contamination); fruit and vegetable processing requires low-residual chlorine disinfected water to protect product freshness; meat processing requires wastewater treatment and recycling to reduce environmental impact. Each sector has tailored water quality indicators and treatment processes.

- What core technologies are used in pure water preparation for the food industry?

The main technologies include reverse osmosis (RO), ultrafiltration (UF), and electrodeionization (EDI). RO is the core technology for removing dissolved salts and microorganisms; UF is used for semi-pure water preparation or RO pretreatment; EDI is combined with RO to produce ultra-pure water for high-end food production.

- How do SKE & Eagle’s water treatment solutions support food industry customers?

SKE & Eagle provides customized water treatment solutions based on raw water quality and production needs, including purification pretreatment, pure water preparation, disinfection, and recycling systems. All systems adopt food-grade materials and hygienic design, complying with global standards. Additionally, SKE & Eagle offers maintenance services, operator training, and spare parts support to ensure long-term stable operation of systems.

- What regulatory standards must food industry water treatment systems comply with?

Key standards include WHO Drinking Water Guidelines, FDA 21 CFR Part 129, EU EC 1935/2004, 3-A Sanitary Standards, and EHEDG guidelines. These standards define water quality indicators, material requirements, and hygienic design requirements, ensuring water safety and regulatory compliance.

Contact SKE & Eagle for Customized Food Industry Water Treatment Solutions

For more technical guidance or to discuss your food processing water treatment requirements, please visit our contact form. Our engineering team is ready to provide expert consultation tailored to your application needs, including raw water analysis, process design, equipment manufacturing, and after-sales service.

Follow us on Facebook or reach out via email at info@ske-eagle.com.