- Overview of Pharmaceutical Grade Water

- Pharmaceutical Water Quality Standards and Compliance

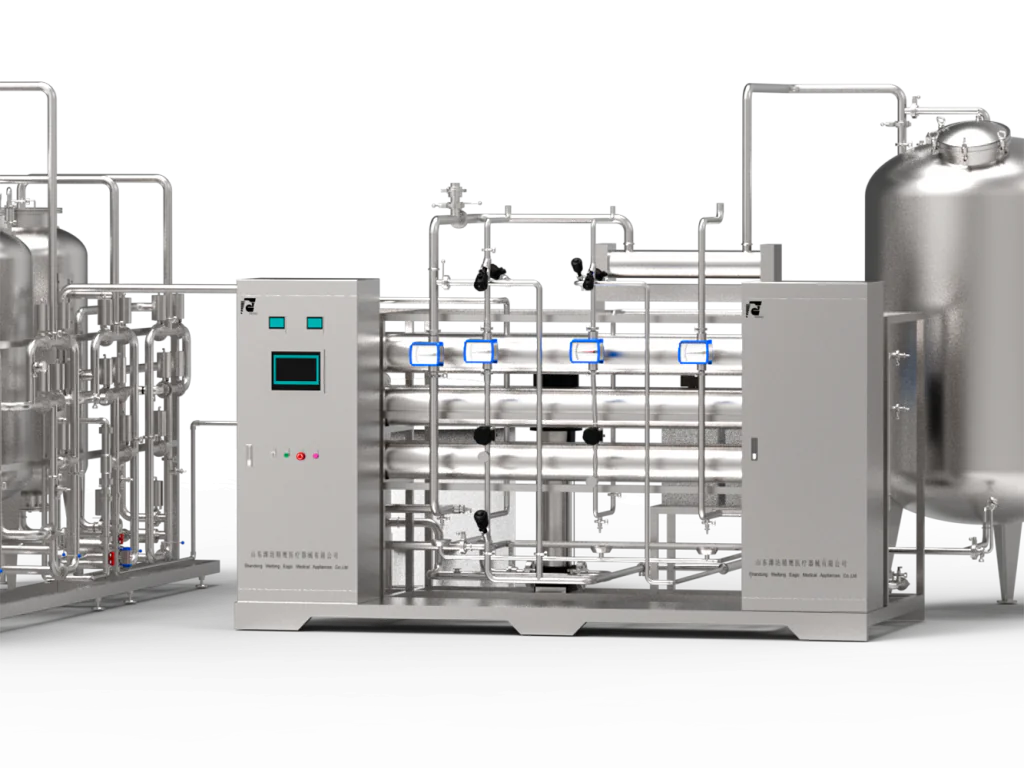

- Core Production Methods and Technologies

- System Design and Engineering Principles

- Validation, Monitoring, and Maintenance Strategies

- Common Challenges and Myths in Pharmaceutical Water Production

- Frequently Asked Questions

Overview of Pharmaceutical Grade Water

Pharmaceutical grade water is a critical raw material in the manufacture of medicinal products, parenteral formulations, and numerous other pharmaceutical preparations. The purity of water directly affects drug safety, efficacy, and patient health, making the rigorous production of pharmaceutical grade water an indispensable part of pharmaceutical manufacturing operations.

In the context of pharmaceutical water production, “”pharmaceutical grade water”” typically refers to water meeting predefined criteria as delineated by official pharmacopeias, such as the United States Pharmacopeia (USP), European Pharmacopeia (EP), or Japanese Pharmacopeia (JP). These waters include categories like Purified Water (PW), Water for Injection (WFI), and Sterile Water for Injection, each with different specifications regarding microbial content, endotoxins, and chemical impurities.

The production of pharmaceutical grade water demands an integrated approach combining source water analysis, advanced purification technologies, robust system design, and continuous quality verification. SKE & Eagle specializes in custom-engineered water purification systems built to satisfy the stringent requirements of pharmaceutical companies worldwide, blending industrial-scale capabilities with precise quality control.

This comprehensive article explores the best practices, technological advancements, regulatory compliance, and engineering foundations behind pharmaceutical grade water production. Whether you are an engineer, quality assurance professional, or pharmaceutical stakeholder, this guide will deepen your understanding of ensuring optimal water quality for pharmaceutical applications.

Pharmaceutical Water Quality Standards and Compliance

Adherence to rigorous water quality standards is fundamental in pharmaceutical grade water production. These standards define allowable limits on microbial populations, endotoxin concentrations, chemical contaminants, total organic carbon (TOC), conductivity, and more. The predominant pharmacopeial standards worldwide include:

- United States Pharmacopeia (USP): Defines Purified Water and Water for Injection (WFI) with precise limits on impurities and microbial load.

- European Pharmacopeia (EP): Provides similar quality definitions, often harmonized with USP standards.

- Japanese Pharmacopeia (JP): Tailors standards to local regulatory requirements.

For example, Purified Water must be free of pyrogens and meet strict conductivity or resistivity levels but is not necessarily sterile. Conversely, Water for Injection (WFI) requires extremely low endotoxin levels and sterility, often necessitating distillation or membrane technologies.

Key water quality parameters typically monitored include:

| Monitoring Parameter | Testing Method | Core Monitoring Significance |

| Microbial Counts | Heterotrophic Plate Count (HPC) | Achieve microbial control of the system and avoid bacterial contamination |

| Endotoxin Levels | Limulus Amoebocyte Lysate (LAL) Test | Verify the applicability of water for injection and control pyrogen risks |

| Total Organic Carbon (TOC) | On-line TOC Analyzer Detection | Reflect the degree of organic contamination and its correlation with bioburden |

| Conductivity/Resistivity | Real-time Monitoring by Conductivity Probe | Characterize ionic purity and meet the pharmacopeial limit requirements |

| Physical Parameters (Turbidity/Appearance) | Physicochemical Testing | Rapidly identify particulate contamination and control basic water quality |

Through continued monitoring and validation practices, pharmaceutical water systems maintain compliance over the system lifecycle.

Core Production Methods and Technologies

The production of pharmaceutical grade water relies on a multi-barrier purification strategy that systematically removes chemical, microbiological, and particulate contaminants. Selecting the appropriate technologies depends on the source water quality, desired pharmaceutical water grade, and operational scale.

The most widely implemented purification methods encompass:

1. Pretreatment and Filtration

Pretreatment is necessary to protect downstream systems by removing suspended solids, chlorine, and hardness from feed water sources. Typical pretreatments involve:

- Multimedia filtration: To remove turbidity and particulates.

- Activated carbon filtration: To eliminate chlorine/chloramine, which could damage reverse osmosis membranes or lead to microbial growth.

- Water softening: Ion exchange processes to reduce hardness and scale formation.

Pretreatment optimization is critical and an area where engineering standards such as those observed by providers like SKE & Eagle ensure system reliability and longevity.

2. Reverse Osmosis (RO)

Reverse osmosis is the predominant membrane technology used to achieve high-level water purification by removing dissolved salts, organics, bacteria, and pyrogens. RO membranes force feed water through semi-permeable membranes at high pressure, rejecting contaminants typically >99%.

A well-designed RO system integrated with proper pretreatment and post-treatment is essential in producing USP-grade purified water. SKE & Eagle’s RO solutions feature materials and membranes engineered for pharmaceutical water robustness and compliance.

3. Ultrafiltration (UF) and Nanofiltration (NF)

UF membranes provide an additional barrier for removing viruses and endotoxins, for example, in WFI systems where steam generation is cost-prohibitive. NF applications typically address specific organic and multivalent ion removal.

4. Distillation

Distillation remains a gold standard for WFI production in some regions due to its ability to produce pyrogen-free water without chemical additives. Multi-effect or vapor compression distillation units, custom-engineered for pharmaceutical use, provide absolute microbial and endotoxin removal.

5. Deionization and Electrodeionization (EDI)

Ion exchange resins in deionization units can remove dissolved ions effectively, often paired with EDI technology to provide continuous ion removal with minimal chemical regeneration, improving system sustainability.

6. Ultraviolet (UV) and Ozone Treatments

UV light systems combat microbial contamination by damaging DNA and RNA of microorganisms in the purified water, often incorporated post-RO. Ozone systems can provide oxidation of organic contaminants and microbial control but require meticulous system design to prevent ozone ingress into final water.

7. Storage and Distribution Systems

Maintaining water quality throughout storage and distribution is equally critical. Systems employ sanitary design principles, including:

- Sanitary stainless steel piping and tanks complying with pharmaceutical-grade engineering standards

- Circulation loops to prevent stagnation

- Temperature control to inhibit microbial growth

- Automated sanitization protocols

Integration of these methods within a certified system, such as those engineered by SKE & Eagle, forms a robust and compliant pharmaceutical water production platform.

System Design and Engineering Principles

The engineering philosophy underpinning pharmaceutical grade water production systems emphasizes reliability, consistency, and regulatory compliance. Water system design is not a one-size-fits-all endeavor; it necessitates precise tailoring to user requirements, source water characteristics, and validation mandates.

Key engineering considerations include:

1. Material Selection

Using inert, corrosion-resistant materials is essential to prevent leachables, contamination, and facilitate cleaning. 316L stainless steel, especially with electro-polished surfaces, is the industry-preferred piping and vessel material due to its hygienic properties and durability.

Additionally, SKE & Eagle rigorously selects system components ensuring compatibility with pharmaceutical cleaning agents like Clean-In-Place (CIP) detergents and steam sterilization demands.

2. Sanitary Piping and Process Flow Design

All piping is designed according to sanitary standards to prevent dead legs and facilitate complete drainage. The hydraulic design promotes turbulence to minimize biofilm formation and microbial colonization.

The organization of the treatment steps in series and parallel ensures redundancy and maximum contaminant barrier integrity.

3. Instrumentation and Process Control

Real-time monitoring of critical parameters such as TOC, conductivity, temperature, and microbial indicators is integrated into automated control systems. These controls trigger alarms, initiate sanitization cycles, and generate documentation needed for regulatory compliance.

4. Validation and Documentation Support

System design incorporates features facilitating qualification phases: Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ). SKE & Eagle supports validation activities by providing comprehensive design and operation documentation.

5. Redundancy and System Reliability

To ensure 24/7 availability of pharmaceutical grade water, system redundancy mechanisms are implemented. Parallel RO trains, backup distillation units, and dual monitoring systems safeguard operations.

6. Energy Efficiency and Sustainability

Modern pharmaceutical water systems engineered by SKE & Eagle integrate energy-saving technologies such as heat recovery in distillation and optimized pump designs reducing operational costs while sustaining industry-leading quality standards.

For further insights into pharmaceutical water system engineering, SKE & Eagle’s engineering services and custom solutions demonstrate industry proficiency in meeting complex system requirements.

Validation, Monitoring, and Maintenance Strategies

Maintaining pharmaceutical grade water quality over time requires continuous monitoring, rigorous maintenance, and periodic system validation in alignment with regulatory expectations.

Validation

Water system validation is a critical roadmap that confirms system performance meets the predefined specifications consistently. Validation phases include:

- Installation Qualification (IQ): Verification that system components are installed according to design specifications.

- Operational Qualification (OQ): Confirming the system operates within defined parameters under normal and upset conditions.

- Performance Qualification (PQ): Demonstration of consistent production of water meeting pharmacopeial quality during routine operation.

Subject matter experts at SKE & Eagle provide protocol development and support during these phases to accelerate approval while ensuring compliance readiness.

Monitoring

Real-time monitoring technologies form the backbone of ongoing water quality assurance:

- Continuous TOC analyzers to detect organic contamination spikes.

- Conductivity probes ensuring ionic purity.

- Automated microbial samplers and endotoxin testing schedules.

- Temperature sensors guarding thermal sanitization efficacy.

Data logging and alarm management systems provide traceability and alert operators to deviations instantly.

Maintenance and Sanitization

Proactive maintenance programs extend system life and prevent contamination events. Key practices include:

- Routine CIP (Clean-In-Place) cycles using approved chemicals.

- Periodic steam or hot water sanitizations where system design permits.

- Replacement of consumables such as RO membranes and filters at manufacturer-recommended intervals.

- Regular inspection of pumps, valves, and instrumentation for functionality.

SKE & Eagle emphasizes customized maintenance schedules backed by engineering analysis optimized for system configuration and operational profiles.

Common Challenges and Myths in Pharmaceutical Water Production

Despite advancements in purification technology and system design, pharmaceutical water production faces persistent challenges and misconceptions that can compromise system design and operation.

Challenge 1: Biofilm Formation and Microbial Control

Biofilm development inside piping or storage tanks can result in microbial contamination despite upstream purification. This challenge requires properly designed sterile surfaces, routine sanitization, and optimized flow patterns. A common myth is that sterile water systems don’t require frequent cleaning; in reality, sanitization protocols are fundamental to microbial control.

Challenge 2: Overreliance on Single Purification Technologies

Some manufacturers mistakenly assume that a single-stage RO or distillation unit suffices. However, multi-barrier purification combining membranes, filtration, and chemical treatments is best practice. SKE & Eagle’s custom solutions capitalize on integrated technology packages tailored to water source and pharmaceutical need.

Challenge 3: Validation Underestimations

Insufficient validation testing or documentation can lead to regulatory setbacks. Continuous collaboration with knowledgeable engineers and compliance experts ensures thorough validation encompassing worst-case conditions.

Challenge 4: Inadequate Distribution System Design

Even after producing pharmaceutical grade water, improper distribution piping design can introduce contaminants. Avoiding dead legs and standing water zones, as well as maintaining sanitized circulation loops, is imperative.

Challenge 5: The Myth of ‘Sterile Water’ in All Pharmaceutical Water

Not all pharmacopeial water grades are sterile. For instance, Purified Water is non-sterile and intended for non-parenteral applications. Confusing this distinction can lead to inappropriate system designs or quality assumptions.

Understanding and resolving these challenges with evidence-based engineering practices such as those provided by SKE & Eagle’s pharmaceutical water expertise is essential for lasting system success.

Frequently Asked Questions about Pharmaceutical Grade Water Production

1.What is pharmaceutical grade water used for?

Pharmaceutical grade water is primarily used as a critical raw material in drug formulation, equipment cleaning, and as a solvent in pharmaceutical production processes where high purity and safety are mandatory.

2.How is pharmaceutical grade water different from regular tap water?

Pharmaceutical grade water undergoes extensive purification to remove dissolved solids, microbiological contaminants, endotoxins, and organic impurities, complying with strict pharmacopeial standards which tap water does not meet.

3.What methods are commonly used to produce pharmaceutical grade water?

Methods include reverse osmosis, distillation, ultrafiltration, ion exchange, and UV sterilization arranged in multistage purification systems designed to achieve the required pharmaceutical water quality.

4.How does SKE & Eagle contribute to pharmaceutical grade water production?

SKE & Eagle provides expertly engineered, tailor-made water purification systems employing industry-leading technologies and design philosophy to ensure water systems meet stringent pharmaceutical compliance, sustainability, and reliability standards.

Contact Us for Expert Pharmaceutical Water Solutions

For tailored advice on pharmaceutical grade water system design or to learn how SKE & Eagle can support your water purification needs, please reach out. Connect with us on Facebook, email us at info@ske-eagle.com, or fill out the contact form on our website for prompt, professional assistance.