The Critical Role of Water in the Food Industry & Significance of Water Treatment

Water is an indispensable core resource in the food and beverage industry, serving as a direct raw material, a key medium for processing, and a critical component in hygiene and sanitation procedures. From beverage formulation and dairy production to meat processing and confectionery manufacturing, water quality directly determines product safety, taste, shelf life, and compliance with regulatory standards. Substandard water containing pathogens, heavy metals, organic impurities, or residual chemicals can lead to foodborne illnesses, product spoilage, and severe reputational and financial losses for enterprises.

Against this backdrop, professional water treatment and purification processes have become non-negotiable for modern food manufacturing. Food-grade water treatment not only ensures the removal of harmful contaminants but also achieves precise control of water quality indicators (such as conductivity, total dissolved solids (TDS), and pH value) to meet the specific requirements of different food production processes. Among these, pure water preparation and deep purification technologies are particularly crucial, as they lay the foundation for high-quality food production and help enterprises comply with global food safety regulations.

Key Food-Grade Water Purification Processes & Core Technologies

Food production requires different levels of water purity depending on the application scenario. From raw water pretreatment to advanced pure water preparation, each process stage plays a vital role in safeguarding water quality. Below are the core purification processes widely applied in the food industry:

- Raw Water Pretreatment: The First Line of Defense

Raw water (from municipal supplies, groundwater, or surface water) often contains suspended solids, colloids, and large particles that can damage subsequent precision equipment. Pretreatment processes typically include:

- Filtration: Sedimentation filters and multi-media filters (sand, activated carbon) remove suspended impurities and organic matter, reducing turbidity and odor.

- Softening: Ion exchange or membrane softening processes reduce calcium and magnesium ions in water, preventing scale formation in heating equipment (e.g., pasteurizers) and pipelines, which can affect heat transfer efficiency and contaminate products.

- Disinfection Preliminary: Chlorination or ultraviolet (UV) disinfection初步 eliminates pathogenic bacteria, reducing the microbial load for subsequent processes.

- Pure Water Preparation: Meeting High-Purity Requirements

Many food processes (e.g., beverage production, dairy product formulation, and food additive manufacturing) require pure water with low TDS and minimal impurities. Core pure water preparation technologies include:

- Reverse Osmosis (RO): As a core technology for pure water production, RO systems use semi-permeable membranes to remove 99% of dissolved salts, organic matter, bacteria, and viruses. The RO process operates under pressure, forcing water molecules through the membrane while rejecting contaminants—a critical step in achieving food-grade pure water standards. SKE & Eagle’s RO systems are engineered with food-grade membrane materials and hygienic designs, ensuring stable pure water output for sensitive food production processes.

- Ultrafiltration (UF): UF membranes with smaller pore sizes remove colloids, proteins, and large molecular weight impurities, often used as a pretreatment for RO systems or for producing water for dairy and beverage processes that require moderate purity.

- Electrodeionization (EDI): A advanced technology that combines ion exchange and electrodialysis, EDI produces high-purity water (ultrapure water in some cases) without the need for chemical regeneration, making it ideal for food processes with strict environmental and purity requirements.

- Deep Purification & Post-Treatment: Ensuring Final Safety

After pure water preparation, post-treatment processes are often required to meet specific process needs and ensure final water safety:

- UV Sterilization: A chemical-free disinfection method that uses UV light to inactivate bacteria, viruses, and protozoa. SKE & Eagle’s food-grade UV sterilizers feature hygienic, easy-to-clean designs, ensuring no residual contaminants and consistent disinfection efficacy—critical for water used in direct food contact.

- Ozone Disinfection: Effective in removing organic matter and inactivating microbes, ozone decomposes into oxygen without leaving residues, making it suitable for water used in beverage and fruit processing.

- Polishing Filtration: Precision filters (e.g., 0.22μm membrane filters) remove any remaining fine particles or microbes, ensuring the water meets the strictest food safety standards.

Food-Grade Water Treatment Equipment: Key Materials & Sanitary Design Principles

- Critical Materials for Food-Grade Water Equipment

Materials used in food-grade water treatment equipment must be non-toxic, inert, and resistant to corrosion and chemical leaching, as they come into direct contact with water used for food production. Key materials include:

- Stainless Steel (Grades 304 & 316L): The gold standard for food-grade equipment. Grade 316L, in particular, contains molybdenum, providing superior resistance to chlorides and harsh cleaning chemicals—essential for water treatment systems. SKE & Eagle uses 316L stainless steel for critical components (e.g., RO membrane housings, UV reactors) to ensure long-term reliability and safety.

- Food-Safe Plastics: High-density polyethylene (HDPE), polypropylene (PP), and polytetrafluoroethylene (PTFE) are used for non-metallic components (e.g., filter cartridges, tubing) due to their chemical inertness and ease of cleaning.

- Specialized Coatings: Electropolishing of stainless steel surfaces reduces roughness, preventing bacterial adhesion and enhancing cleanability— a standard practice in SKE & Eagle’s manufacturing process.

- Sanitary Design: Preventing Secondary Contamination

Sanitary design is critical for food-grade water treatment equipment to avoid secondary contamination during operation and cleaning. Key design principles include:

- Smooth, Non-Porous Surfaces: Eliminating crevices and uneven surfaces where bacteria can hide.

- Full Drainability: Equipment is designed to drain completely without puddling, preventing microbial growth.

- Minimized Dead Legs: Pipework and connections avoid blind spots that are difficult to clean, ensuring thorough sanitization.

- Compatibility with CIP (Clean-in-Place) Systems: All components withstand high-temperature cleaning and caustic/acidic detergents, enabling efficient and effective sanitation without disassembling equipment. SKE & Eagle’s water treatment systems are fully CIP-compatible, reducing downtime and ensuring consistent hygiene.

Manufacturing Standards & Quality Assurance for Food-Grade Water Equipment

To ensure the safety and reliability of food-grade water treatment equipment, strict manufacturing standards and quality assurance processes are essential. Key requirements include:

- Material Traceability: Comprehensive documentation of material certificates to confirm compliance with food-grade standards (e.g., FDA approval for contact materials).

- Sanitary Welding: Adherence to ASME BPE (BioProcessing Equipment) standards for welding, ensuring smooth, hygienic welds that do not trap contaminants.

- Rigorous Testing: Pressure testing, leak testing, and performance validation (e.g., RO membrane rejection rate, UV disinfection efficacy) to ensure equipment operates as designed.

- Quality Management Systems (QMS): Implementation of ISO 9001 and other international QMS standards to ensure consistent quality across all production stages. SKE & Eagle maintains a robust QMS, with in-house inspections and third-party audits to validate compliance.

Regulatory Compliance & Certifications for Food-Grade Water Treatment

Food-grade water treatment equipment and processes must comply with strict national and international regulations to ensure water safety for food production. Key regulations and certifications include:

- FDA 21 CFR Part 110 & Part 177: U.S. regulations specifying requirements for food manufacturing facilities and food contact materials, including water treatment equipment components.

- EU Regulation (EC) No 1935/2004: Governs materials and articles intended to come into contact with food in the European Union, setting limits for migration of harmful substances.

- NSF/ANSI Standards (e.g., NSF 58 for RO systems): Certifications ensuring water treatment equipment meets public health and safety standards.

- 3-A Sanitary Standards: Widely recognized in the dairy and beverage industries for hygienic equipment design and performance.

SKE & Eagle’s food-grade water treatment solutions are fully compliant with these global regulations. The company maintains comprehensive documentation (e.g., Material Safety Data Sheets, Certificates of Analysis) and undergoes third-party certification to ensure audit readiness for customers worldwide.

SKE & Eagle: Engineering Excellence in Food-Grade Water Treatment Solutions

With decades of experience in industrial water treatment, SKE & Eagle has established itself as a trusted provider of food-grade water purification solutions, combining engineering expertise, hygienic design, and regulatory compliance to meet the unique needs of the food industry.

SKE & Eagle’s core food-grade water treatment solutions include:

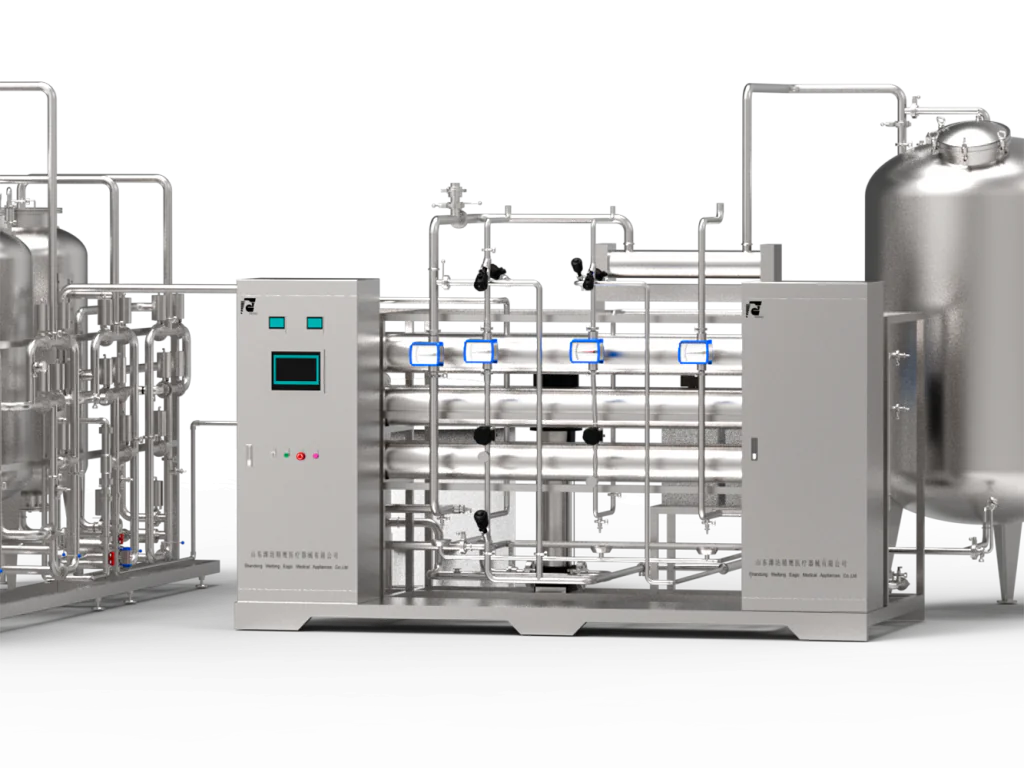

- Custom RO Pure Water Systems: Tailored to different production scales and purity requirements, featuring 316L stainless steel components and food-grade membranes for stable, reliable pure water output.

- UV Sterilization Systems: Hygienically designed UV reactors with high-efficiency lamps, ensuring 99.99% inactivation of bacteria and viruses without chemical residues.

- Integrated Water Treatment Packages: Comprising pretreatment, pure water preparation, and post-disinfection modules, designed for seamless integration with food processing lines to minimize downtime and maximize efficiency.

SKE & Eagle’s commitment to quality is reflected in its rigorous manufacturing processes, from material selection and sanitary welding to performance testing and validation. The company’s team of engineers works closely with customers to understand their specific production needs, delivering customized solutions that comply with local and global regulations while optimizing operational efficiency.

By prioritizing safety, reliability, and innovation, SKE & Eagle helps food manufacturers safeguard product quality, comply with regulatory requirements, and build consumer trust—making it a preferred partner for food-grade water treatment solutions worldwide.

Frequently Asked Questions (FAQs) About Food-Grade Water Treatment

- Why is water treatment critical for the food industry?

Water is a key raw material and processing medium in food production. Impure water can introduce pathogens, heavy metals, and chemicals, leading to foodborne illnesses, product spoilage, and regulatory non-compliance. Water treatment ensures water quality meets food safety standards, protecting consumer health and enterprise reputation.

- What is the difference between pure water and regular water in food production?

Pure water has significantly lower total dissolved solids (TDS), bacteria, and impurities compared to regular tap or raw water. It is required for processes where water quality directly affects product taste, texture, and shelf life (e.g., beverage formulation, dairy production), while regular treated water may be used for non-direct contact applications (e.g., equipment cleaning).

- What core technologies are used in food-grade pure water preparation?

The main technologies include reverse osmosis (RO) for removing dissolved salts and impurities, ultrafiltration (UF) for removing colloids and large molecules, and electrodeionization (EDI) for producing high-purity water without chemical regeneration.

- How does SKE & Eagle ensure the safety of its food-grade water treatment equipment?

SKE & Eagle uses food-grade materials (e.g., 316L stainless steel), adheres to sanitary design principles, complies with global regulations (FDA, EU 1935/2004), and implements rigorous quality control processes (material traceability, welding inspections, performance testing) to ensure equipment safety and reliability.

- Can SKE & Eagle provide customized water treatment solutions for specific food processes?

Yes. SKE & Eagle’s team of engineers assesses customer needs (e.g., production scale, desired water purity, regulatory requirements) to design and manufacture customized solutions, including integrated pretreatment, pure water preparation, and post-disinfection systems tailored to specific food production processes.

Connect with SKE & Eagle for Your Food-Grade Water Treatment Needs

For more insights into food-grade water treatment solutions and how we can support your operations with industry-leading technology and engineering expertise, we invite you to reach out.

Engage with us on Facebook or contact us directly via email at info@ske-eagle.com. Please also visit our website to fill out the contact form at the bottom of the page for tailored assistance and project consultation.